WELDING Fittings – Connecting Aluminum-Multi-Layer Pipe Innovatively

Description

In addition to the press- and push-fittings, we have also combined the welding connection with the advantages of the aluminum-multi-layer pipe. This provides the user with another economical solution for the installation.

The flexibility of the aluminum-multi-layer pipes significantly increases handling, as many fittings can be saved.

Precision

- Large dimensional range from 16 mm to 75 mm

- Homogeneous, friction-locked connection for a secure and durable installation

- Advantages from two worlds: The simple welding technique can now be used with the flexibility of the aluminum-multi-layer pipe.

Video

PE-RT WELDING Fittings

Welding with more advantages

Installation with welding connections is a well-known connection method. MULTITUBO systems was the first system to combine the advantages of the aluminium-multi-layer pipe with welding technology. This resulted in a connection that brings significantly more advantages to the construction site than traditional systems.

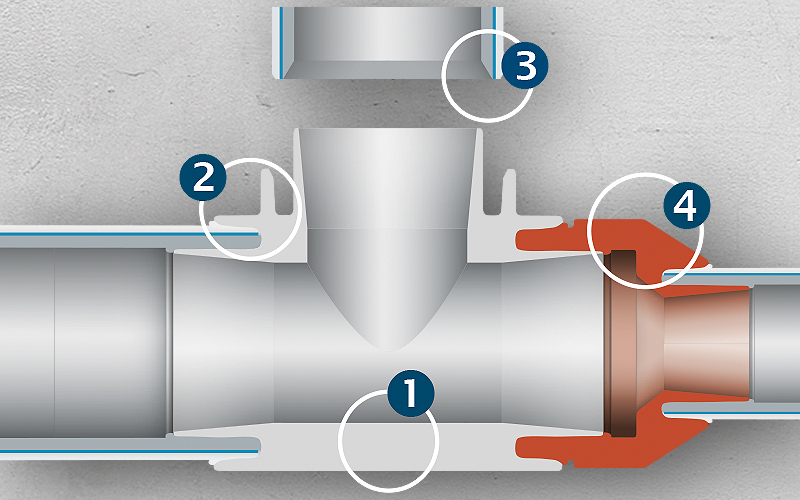

Fitting structure

1: Fitting body consists of PE-RT, a polyethylene with increased temperature resistance.

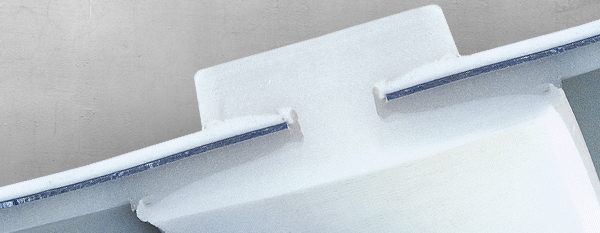

2: The welding profile

is specially shaped so that the heated material finds its way in a controlled manner.

3: The aluminium layer

is optimally protected by welding on the inner and outer layers of the pipe.

4: Reductions

are made easy by a wide range of adapters.

The Connection

Homogeneous and friction-locked

The same material for fittings and pipe ensures a weld with optimal material flow. The homogeneous and friction-locked connection is the basis for a durable joint. The heating time of the material is short due to the low insertion depth and the connection is thus quickly completed. Peeling of the pipe is not necessary and facilitates handling.

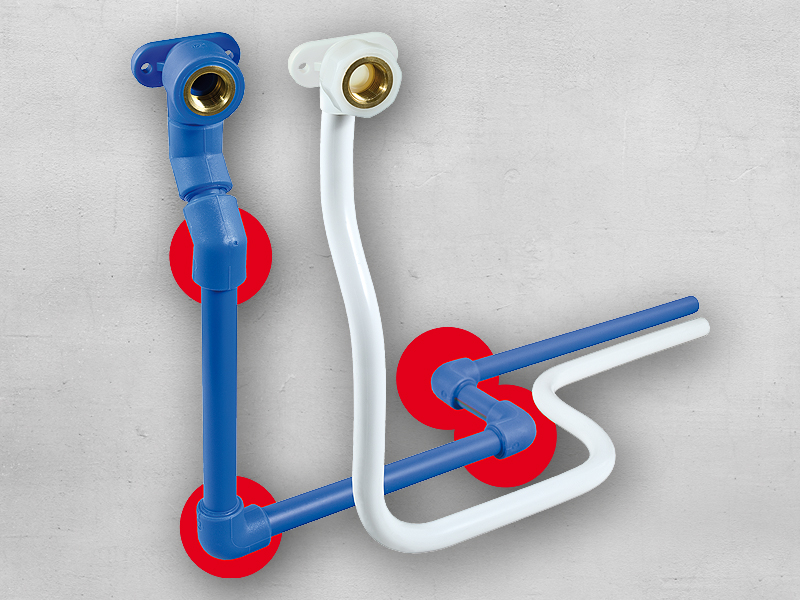

Flexibility

Due to its structure as a composite material, the aluminum-multi-layer pipe can be easily bent in small dimensions and retains this shape. This makes it easy to change the direction without using fittings, which saves on fittings and working time.