METAL Press Fittings – The Basic Range

Description

The METAL Press Fittings are the basic connection of the entire MULTITUBO systems range. The extensive range covers a wide range of dimensions and offers many special parts.

For contract installations, the MODULAR Press Fitting range extends the dimensions up to 110 mm. This range also makes handling large dimensions much easier, especially when working overhead.

Precision

- Large dimensional range from 16 mm to 110 mm

- U-contour for the secure and proven connection

- Permanently tight connection with O-rings

- Stainless steel press sleeves

- Inspection window for easy checking of the pipe insertion depth

Video

METAL Press Fittings

16 mm - 75 mm

The basic body of the fitting is made of tin-plated brass according to the UBA harmlessness list. With the large depth of the range, many other applications, such as crossing-free pipe laying, the connection of concealed cisterns and baseboard connections, are also possible without any problems.

16 mm - 32 mm

40 mm - 75 mm

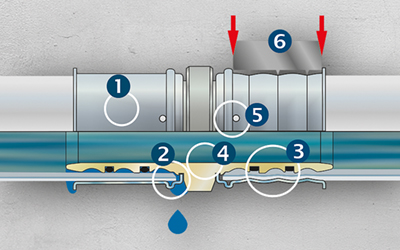

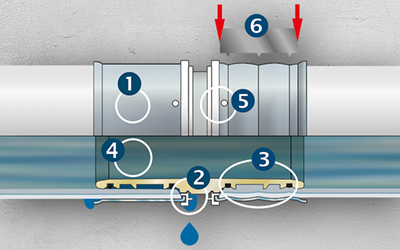

Fitting structure

1: The stainless steel press sleeve

enables safe positioning of the press jaws even in difficult-to-access construction site situations.

2: The additional test security

(16 mm - 32 mm) shows unpressed joints already during the pressure test.

3: 2 O-rings

for the permanently tight connection

4: Fitting body

made of tin-plated brass

5: The inspection windows

for safe control of the correct insertion depth of the pipe.

6: The press contour

All press fittings are to be pressed with the U-press contour.

G2 Press Fitting – The new fittin generation

The basic body of the fitting is made of tin-plated brass according to the UBA harmlessness list. With the large depth of the range, many other applications, such as crossing-free pipe laying, the connection of concealed cisterns and baseboard connections, are also possible without any problems.

MODULAR Press Fittings

25 mm - 110 mm

The basic fitting body of the adapters is made of tin-plated brass, the fittings and press sleeves of stainless steel. This makes the large dimension fittings lighter and easier to handle. This is particularly useful when working overhead, because the adapters, which are pressed at the workbench, are connected on site with a clamp and seal.

75 mm - 110 mm

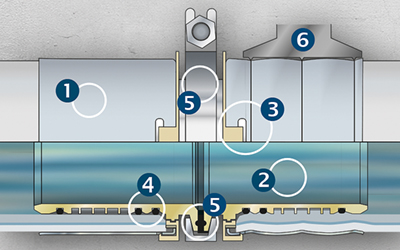

Fitting structure

1: The stainless steel press sleeve

for a secure fit of the press jaws.

2: Fitting body

made of tin-plated brass

3: Press chain stop and inspection window

for easy checking of the correct fit of tube and press chain.

4: 2 O-rings

for a permanently tight connection

5: The connection with the clamp

Clamp and seal secure the connection and can be joined easily and quickly on site.

6: The press contour

All press fittings are to be pressed with the U-press contour.