G2 - THE NEW FITTING GENERATION

Description

The new G2 fitting perfects our proven connection technology with a range of innovative features.

It is the consistent further development of our press fitting system – making installation even easier and safer.

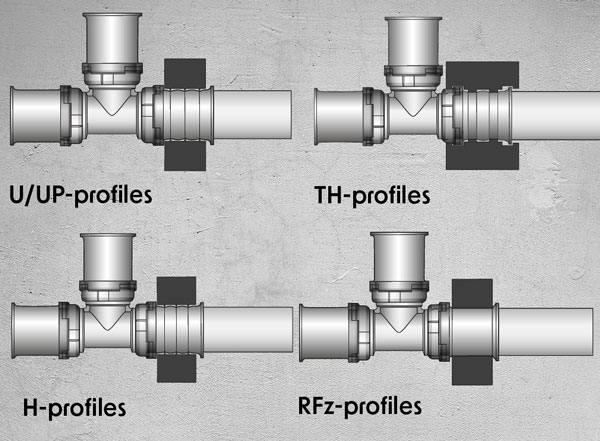

In addition, the G2 fitting is compatible with even more pressing profiles (U, TH, H, and RFz), making it the ideal solution for all professional tradespeople.

The G2 fitting is available in dimensions ranging from 16 to 32 mm and comes in both lead-free brass and a cost-effective PPSU variant.

Features

- MORE PRESS PROFILES

- NO MORE DEBURRING

- UNPRESSED AND LEAKING

- 360° INSPECTION WINDOW

- FLOW-OPTIMIZED

- NEW SLEEVE INSCRIPTION

- NEW PROFILE GEOMETRY

- DOUBLE PRESS JAW STOP

- SLIM DESIGN

G2 Press Fittings

Easy to install

360° viewing window

In order to make daily work easier, the stop ring can be viewed

through 360°. This allows a good view for checking the insertion

depth of the pipe.

No more deburring

The O-rings are protected in the profi le and also allow the use of

non-deburred pipes in the dimensions 16 mm to 25 mm. However, we

still recommend deburring the pipe ends to ensure that the connection

is made as gently as possible.

Best performance and safety

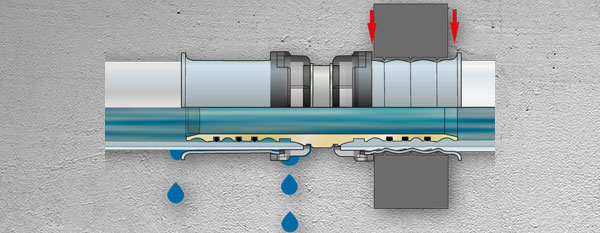

Unpressed and leaking

The fitting has been tested in accordance with DVGW worksheet W 534, unpressed and leaking.

Flow optimized

With an average of 20% more power, designing the installation is easier, even in borderline areas.

Versatile

More press profiles

The new fitting generation can now be pressed with 4 press profiles.

A clear gain of more flexibility in tool and cost management.

Double press jaw stop

and slim design In order to make the daily work process as safe and simple as before, we have certainly retained the double-sided press jaw stop and the slim design.